Automation has recently gained popularity across a wide range of businesses, most notably through businesses looking at ways to enhance the production of their warehouses and factories. Warehouse automation is an incredibly efficient approach to relieve stress on your staff while guaranteeing higher levels of productivity than you can often achieve on your own. Read More…

A recognized leader in automated assembly products. Stay competitive with Dixon's robotic screwdrivers, auto-fed screw & nut drivers, auto-fed part placers, parts feeding systems & assembly cells, including robotic assembly & vision. Every Dixon product is manufactured to assure accuracy & dependability for repetitive assembly. Dixon supports Machine Integrators with assembly products & stations. ...

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

Advent design has been in business for over 35 years providing custom automation solutions, engineering, integration solutions and machine safety services. Contact us today to discuss your project needs and see how we can help you achieve your goals.

Since 1982, Isotech has been a leader in the automation equipment industry. You can trust the accuracy of our solutions. Our experts at Isotech are always available to assist you with your needs. Feel free to contact us today to learn more information!

We have an extensive selection of products to pick from and we are confident we can find the perfect solution for your application. Our world-class items are proven for reliability and longevity. You can count on us to supply you with the best.

Del-Tron Precision is your one-stop shop for ball & crossed roller slides, multi-axis positioning and motor-ready lead screw stages, air actuators, recirculating slide guides and crossed roller rail sets. Custom linear slides are available.

More Warehouse Automation Manufacturers

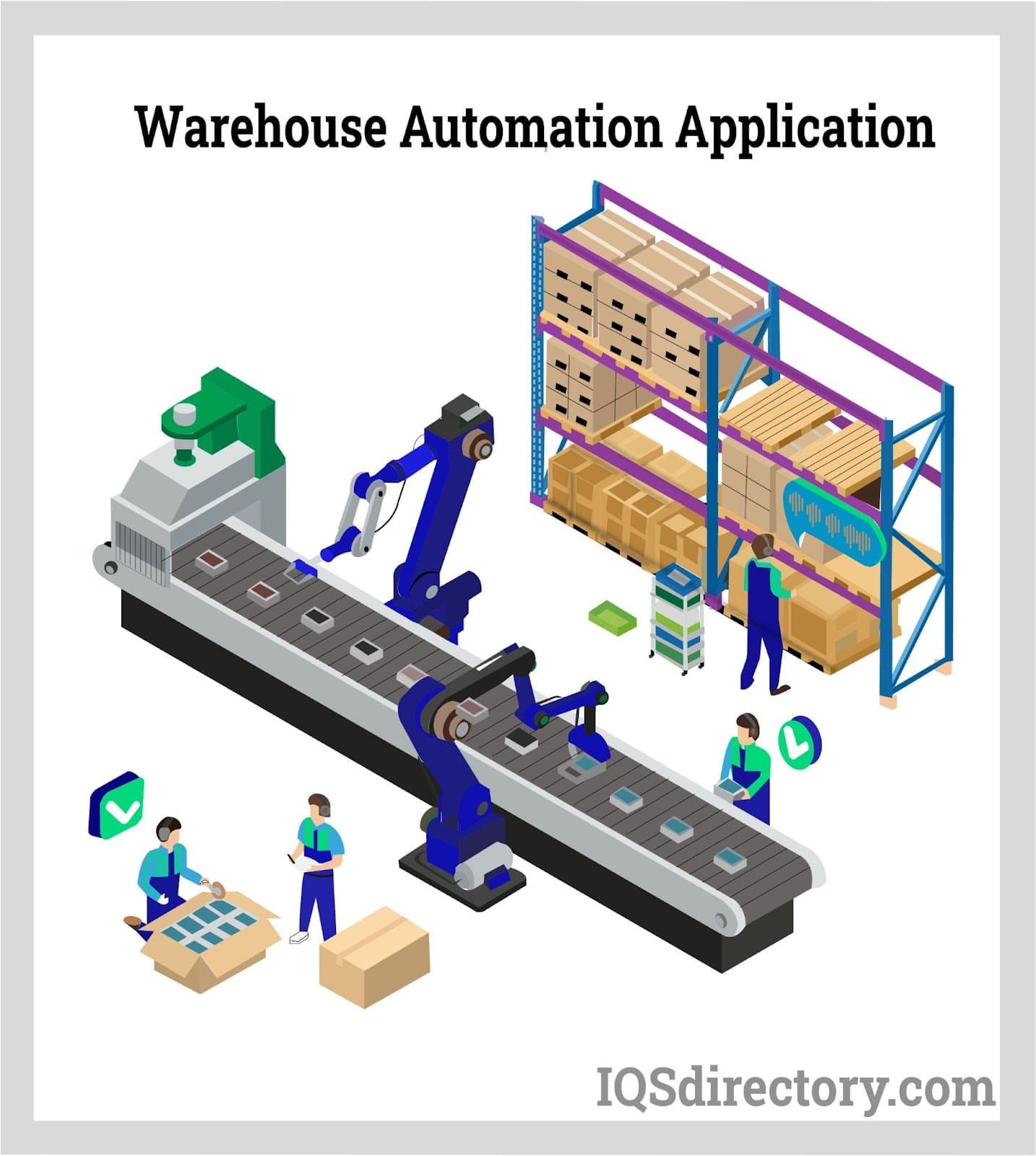

Many of the crucial tasks that sustain your warehouse e.g. receiving, sorting, storing or picking, packing, shipping, replenishment, and returns, can all be aided by warehouse automation. A lot of the operations in your warehouse can now be automated with today's technology.

What is Warehouse Automation?

Warehouse automation may be defined in more than one form. It includes the tools and robots that help staff with operations involving inventory from the time materials enter the warehouse until a finished piece leaves. Using warehouse automation systems may lower labor costs, boost safety, and increase productivity and accuracy for warehouses.

Under one definition, warehouse automation can be regarded as businesses using machines' accuracy and endurance to constantly perform repetitive jobs for extended periods of time without getting tired. Humans are still involved in some warehouse automation solutions, which handle anything from unloading containers to order fulfillment.

Types of Warehouse Automation

Warehouse automation can be achieved in numerous ways, each having its own unique advantages. Under the general heading of "warehouse automation," many technologies that support human workers or independently complete activities from beginning to end are included under this term. Below are some of the noteworthy types of warehouse automation technologies:

Collaborative Mobile Robots

Collaborative mobile robots support workers during the picking process to increase picking accuracy and productivity. Some collaborative mobile robots optimize picking routes and jobs based on the status of the warehouse and the priority of the workload. Collaborative mobile robots provide many advantages, such as adaptability, dependability, scalability, shorter walking distances, and higher productivity.

Sortation Systems

Sortation systems use a variety of technologies to detect and separate things, guiding these items to specified places for returns processing, picking zones, or packaging stations. Sortation systems also help direct products to the right locations or to the relevant bins.

Pick-to-Light Systems

Pick-to-light systems assist employees in finding the right items to satisfy orders by using LED lights and barcodes. Pick-to-light systems supplement human labor by minimizing walking and increasing efficiency by quickly identifying an item’s location for pickers.

Automated Storage & Retrieval Systems

Automation can be used to store and retrieve items via automated storage and retrieval systems, or AS/RS systems. Automatic guided vehicles that travel along wires or magnetic strips can be found in many warehouses. Robots that are autonomously mobile and equipped with laser guidance systems may maneuver through more-complicated warehouse environments, including those that may have more frequent foot activity in general. Systems for automatically categorizing inventories are also employed to help assist in delivering goods to the appropriate areas.

Benefits of Warehouse Automation

Some of the prominent benefits of warehouse automation are given below:

- Increased contentment among employees by reducing boring, repetitive, or dangerous tasks

- Improved data analysis and accuracy

- Fewer instances of stockouts

- Optimized warehouse layout

- Improved inventory management

- Enhanced workplace security

- Fewer shipping mistakes

- Reduced loss from inventory

- Enhanced coordination of material handling

- Increased accuracy of order fulfillment

Applications of Warehouse Automation

The following is just a very small sample of the industries employing warehouse automation technologies along with a basic understanding of why, or where, this automation is used by these industries:

- Automotive- from making various automotive components to delivering parts to workers

- Food packaging- for increasing quality and hygiene standards by removing workers from stages of production

- Medical- for monitoring product expiration dates and providing more accurate picking

- Construction- by storing, sorting, and retrieving the equipment needed for a job

- Plastics- for reasons ranging from removing staff from dangerous environments to helping make delicate parts

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services