Assembly machines can be operated manually or by computer, although the computerized aspect of assembly machines is what makes them so popular. The computerized aspect is referred to as CNC machining, or machines run by computer programs such as computer assisted design (CAD) and computer aided manufacturing (CAM) as well as other advanced programming such as photo imaging. Because these programs allow each individual machine to be programmed to repeat a task with very little human interaction, they cut down on costs and increase productivity time. Read More…

A recognized leader in automated assembly products. Stay competitive with Dixon's robotic screwdrivers, auto-fed screw & nut drivers, auto-fed part placers, parts feeding systems & assembly cells, including robotic assembly & vision. Every Dixon product is manufactured to assure accuracy & dependability for repetitive assembly. Dixon supports Machine Integrators with assembly products & stations. ...

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

Advent design has been in business for over 35 years providing custom automation solutions, engineering, integration solutions and machine safety services. Contact us today to discuss your project needs and see how we can help you achieve your goals.

Since 1982, Isotech has been a leader in the automation equipment industry. You can trust the accuracy of our solutions. Our experts at Isotech are always available to assist you with your needs. Feel free to contact us today to learn more information!

We have an extensive selection of products to pick from and we are confident we can find the perfect solution for your application. Our world-class items are proven for reliability and longevity. You can count on us to supply you with the best.

Del-Tron Precision is your one-stop shop for ball & crossed roller slides, multi-axis positioning and motor-ready lead screw stages, air actuators, recirculating slide guides and crossed roller rail sets. Custom linear slides are available.

More Assembly Machine Manufacturers

The original assembly line in 1908, developed by a team of engineers including Henry Ford did not involve much assembly machinery yet. Instead it was an organizational system, directing a group of workers to perform a single step in the process of producing a product rather then doing every step for one product from beginning to end. This sped up production to such an extent that producing cars, which was Henry Ford's business, went from taking hours to taking minutes. The technological advances of our modern society have pushed this idea into a new realm of mass production.

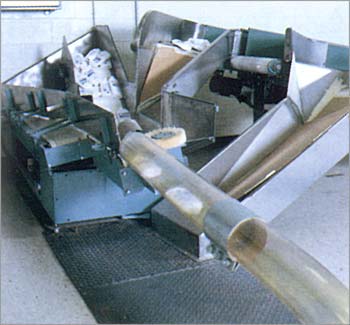

What was done by many human hands in 1908 is now done by many manufacturing automation machines. These automated assembly machines are capable of performing a wide variety of tasks, including riveting, brazing, welding, eyeleting, metal injecting, screw driving, nut driving and soldering. They are faster, more accurate and more efficient than their human counterparts.

Human workers are now employed as practitioners of machine maintenance and overseeing the quality of the products coming from the assembly lines. Most assembly machines require regular monitoring and lubrication in order to continue to run smoothly and well. Although this means fewer workers are necessary in a manufacturing factory, it does require an educated employee who understands the intricacies of machinery and is very observant.

When assembly machines are involved, the human counterparts are now about quality mind power rather then the quantity employed. A vast number of industries utilize assembly machines, including aerospace, automotive, medical suppliers and food and beverage processing plants. Large products, such as cars and major sections of ships may be produced by assembly lines just as easily as the small products such as cell-phones, screws, gears, and computer pieces.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services