The use of technology and systems to automate a manufacturing process, known as “factory automation,” is implemented with the ultimate objective of boosting output and cutting costs. The degree of automation can range from partial automation of a specific task to complete automation without human involvement. In a fast-evolving modern factory environment, factory automation offers a compelling solution to improve quality, efficiency, safety, sustainability, and security. In addition, factory automation offers a route toward optimum profitability and superior performance when competition intensifies and margins are compressed. Automation uses hydraulic, pneumatic, and robotic arms in production environments to build increasingly complicated systems. Read More…

A recognized leader in automated assembly products. Stay competitive with Dixon's robotic screwdrivers, auto-fed screw & nut drivers, auto-fed part placers, parts feeding systems & assembly cells, including robotic assembly & vision. Every Dixon product is manufactured to assure accuracy & dependability for repetitive assembly. Dixon supports Machine Integrators with assembly products & stations. ...

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

Advent design has been in business for over 35 years providing custom automation solutions, engineering, integration solutions and machine safety services. Contact us today to discuss your project needs and see how we can help you achieve your goals.

Since 1982, Isotech has been a leader in the automation equipment industry. You can trust the accuracy of our solutions. Our experts at Isotech are always available to assist you with your needs. Feel free to contact us today to learn more information!

We have an extensive selection of products to pick from and we are confident we can find the perfect solution for your application. Our world-class items are proven for reliability and longevity. You can count on us to supply you with the best.

Del-Tron Precision is your one-stop shop for ball & crossed roller slides, multi-axis positioning and motor-ready lead screw stages, air actuators, recirculating slide guides and crossed roller rail sets. Custom linear slides are available.

More Factory Automation Manufacturers

Automation in the factory can be used at any stage of the production process, from material quantities management to production and assembly to packaging and delivery.

Implementation Of Factory Automation

Thanks to factory automation, the same hardware and software system can control different production processes. For instance, the automation should link input devices to a computer, such as handwheels or inching drives, to enable operators to control them remotely. Some factors should be considered to implement factory automation in a certain industry. These include:

Identify Opportunities for Automation

Some processes are more flexible and amenable to automation than others. Therefore, before adopting certain automation in some factory processes, it’s important to determine whether a certain process can be automated. Most procedures amenable to automation usually have both transactional and decisional components. Since transaction components are made up of repetitive parts, they benefit more from automation.

Select A Design Model

After determining which processes are amenable to automation, the user selects the design model that best satisfies the needs of the operations. The process map gives a broad picture of the tasks being carried out and their results and is used in selecting the design model that best suits the requirements of the process. Four design models can be used or selected according to the requirements.

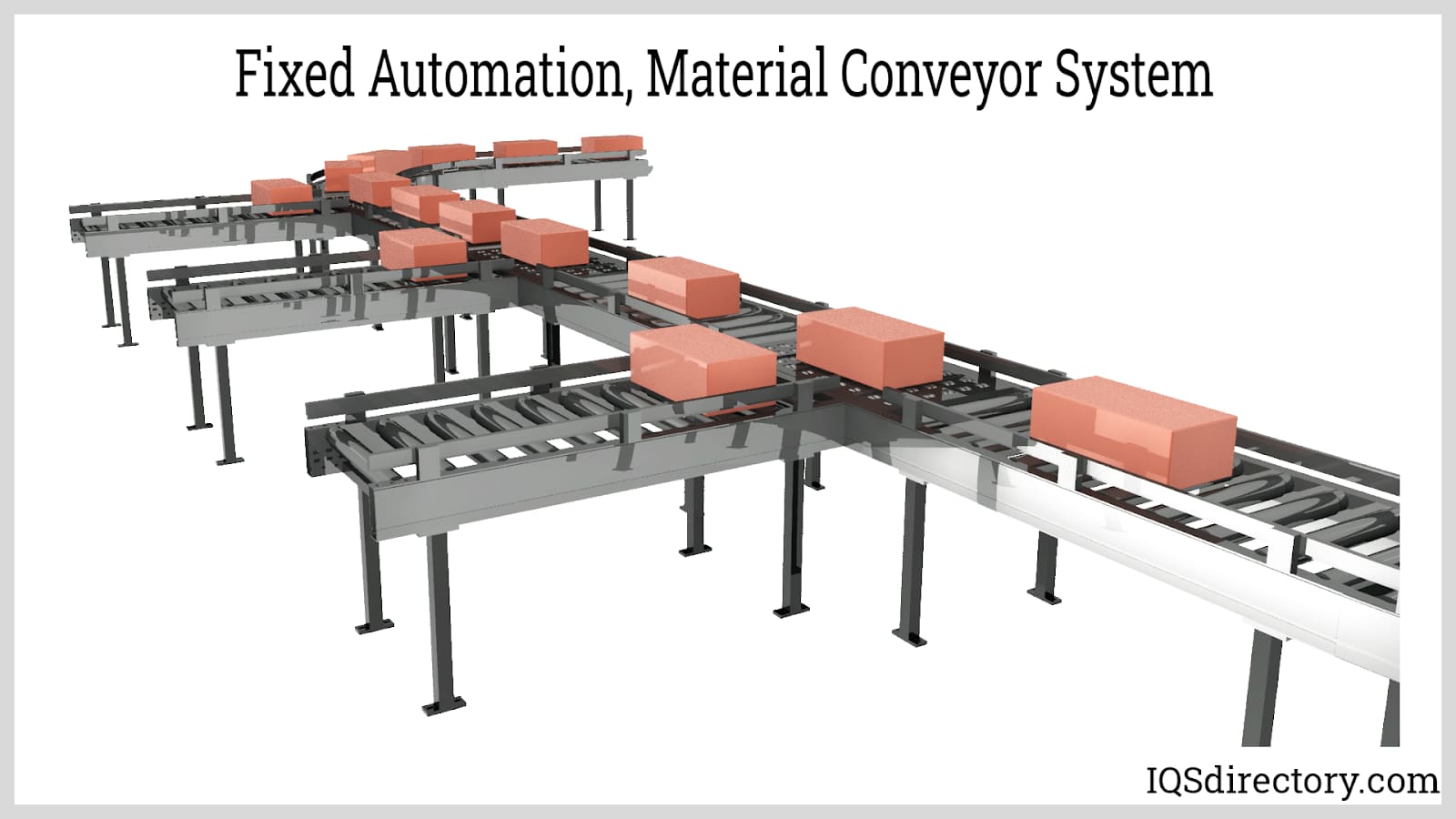

Fixed Automation

Hard automation, also known as fixed automation manufacturing, is a system in which automated production and assembly processes are programmed to create a single product. This system is typically employed in continuous flow systems for mass production. The arrangement of tooling, equipment and machines earmarked for high-volume requirements determines the order of production and operation. Automated assembly lines, chemical production procedures, material handling conveyor systems, paint and coating automation procedures, and process lines are a few examples of stationary automation systems.

Flexible Automation

Flexibility in automation refers to a manufacturing process that can quickly adjust to shifting production requirements, such as product kind and quantity. Humans use computer code to program and operate computerized systems that control machines (Human Machine Interfaces). The system can be programmed or designed to generate several different product types simultaneously. A centralized computer system manages the production and material handling systems. The system is best suited for batch operations for businesses that conduct low- to medium-volume manufacturing runs of various products. Flexible automation involves robotics, assembly systems, and material handling systems.

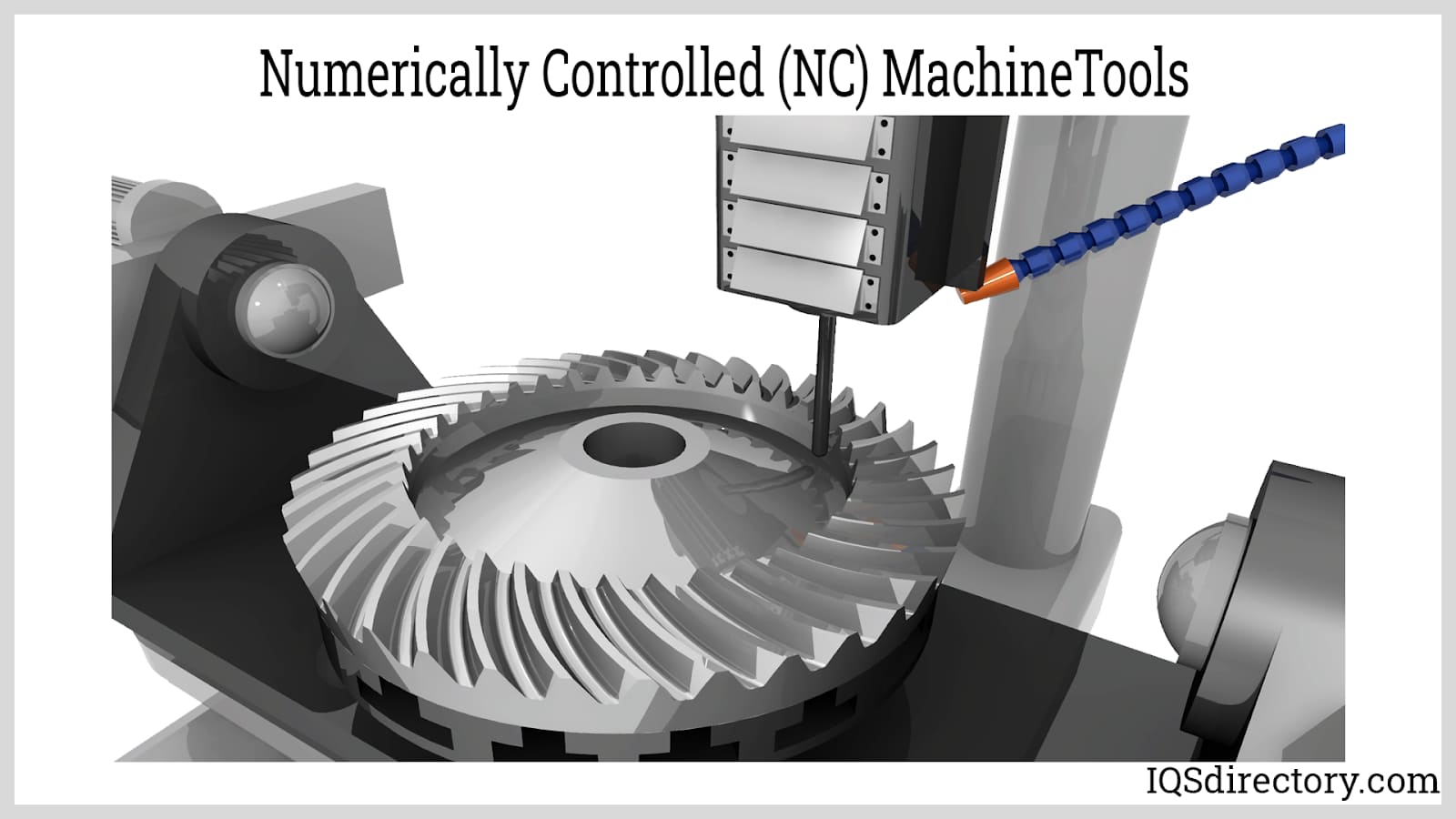

Programmable Automation

The configurations and operational procedures of equipment can be changed thanks to programmable automation when commands are written or programmed into the system. This design uses a series of actions, and electronic controls can modify how the machinery is set up. Typically, batch process production uses this architecture.

Integrated Automation

This design model uses a collection of independent machines, data, and processes. All parts operate in unison under the direction of a single control system. Typically, this paradigm is used to operate conveyors, cranes, and robots.

Testing The New System

Before implementing an automation plan, a certain test must be done to ensure that the system is working well. Different functional needs should be isolated and described by a sound testing method. Tests are selected based on their complexity and predicted outcomes. Therefore, it is crucial to keep human and automated testing tasks separate.

Applications of Factory Automation

Industrial automation is used in a wide range of applications by manufacturing businesses. For example, in paper mills, it can be used to control equipment, plant devices, and manage batch production. The use of autopilot controls on commercial aircraft has long been a feature of factory automation in the airline sector. Additionally, drilling for oil and gas uses factory automation.

Benefits of Factory Automation

- A safer working environment and significant risk reduction are achieved by automating risky processes, incorporating built-in shut-down, and reducing human engagement.

- After the initial investment in automating the system, increased productivity, decreased downtime, lower training costs, and the elimination of accidents led to dramatically enhanced profitability.

- Human error is reduced in processes that continually use machines.

- Because an automated process can be repeated, the outcomes are more consistent, and there are fewer differences due to different operators and other human factors.

- Automating the process allows one to determine how much of a resource is needed while avoiding wasting too much.

Choosing the Right Factory Automation Supplier

To make sure you have the most productive outcome when purchasing Factory Automation from a Factory Automation Company, it is important to compare at least 4 Companies using our list of Factory Automation suppliers. Each Factory Automation Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Factory Automation business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Factory Automation companies with the same form.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services