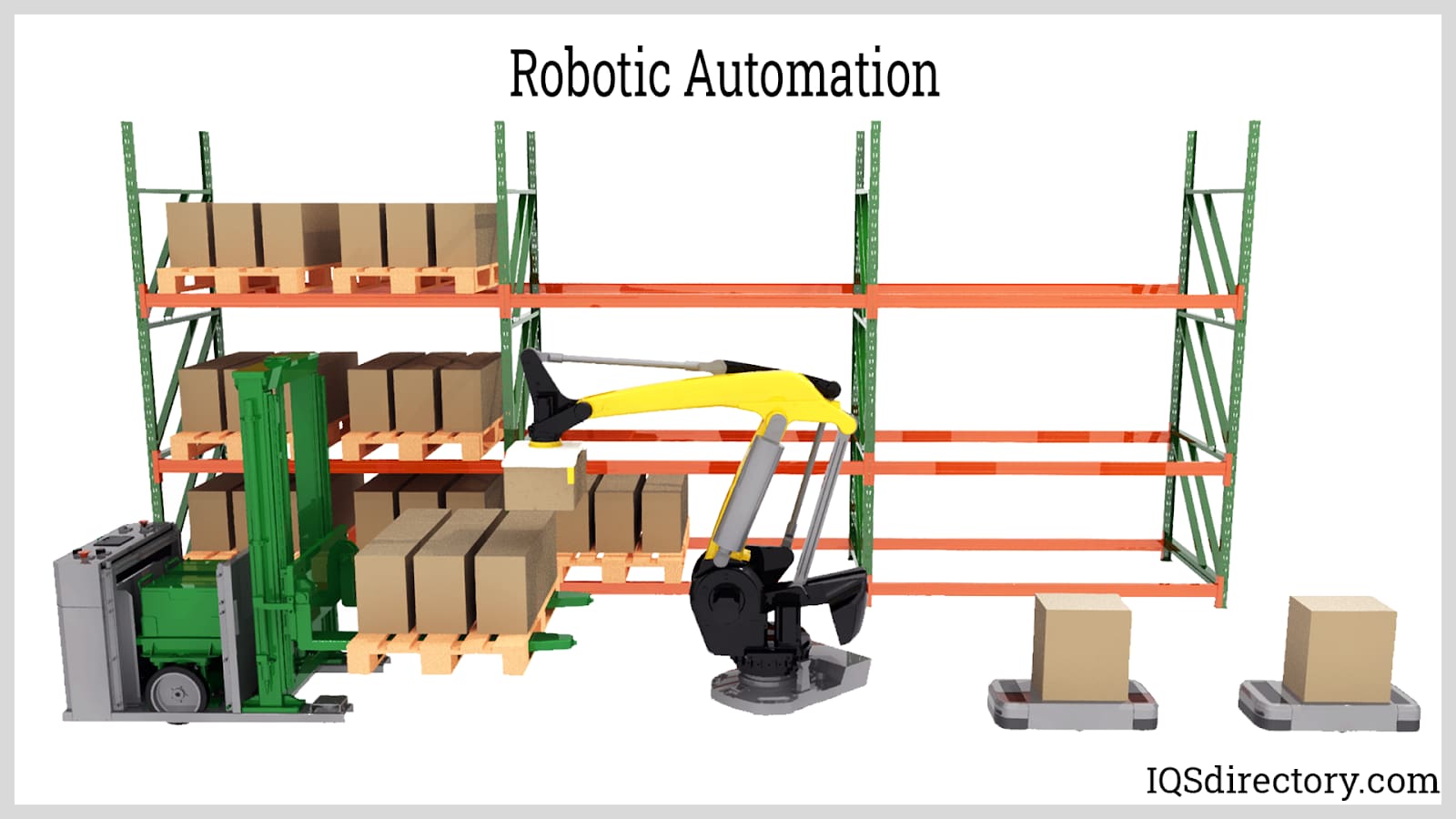

Robotic automation is the use of artificial intelligence and robots to accomplish a variety of tasks at hand. Robotic automation allows companies to be able to program different automated machinery and perform various tasks thereby increasing worker safety and providing employees with more efficient use of their time. Read More…

A recognized leader in automated assembly products. Stay competitive with Dixon's robotic screwdrivers, auto-fed screw & nut drivers, auto-fed part placers, parts feeding systems & assembly cells, including robotic assembly & vision. Every Dixon product is manufactured to assure accuracy & dependability for repetitive assembly. Dixon supports Machine Integrators with assembly products & stations. ...

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

Advent design has been in business for over 35 years providing custom automation solutions, engineering, integration solutions and machine safety services. Contact us today to discuss your project needs and see how we can help you achieve your goals.

Since 1982, Isotech has been a leader in the automation equipment industry. You can trust the accuracy of our solutions. Our experts at Isotech are always available to assist you with your needs. Feel free to contact us today to learn more information!

We have an extensive selection of products to pick from and we are confident we can find the perfect solution for your application. Our world-class items are proven for reliability and longevity. You can count on us to supply you with the best.

Del-Tron Precision is your one-stop shop for ball & crossed roller slides, multi-axis positioning and motor-ready lead screw stages, air actuators, recirculating slide guides and crossed roller rail sets. Custom linear slides are available.

More Robotic Automation Manufacturers

What is Robotic Automation?

Robotic automation is the use of artificial intelligence and robots to accomplish a variety of tasks at hand. Robotic automation allows companies to be able to program different automated machinery and perform various tasks thereby increasing worker safety and providing employees with more efficient use of their time.

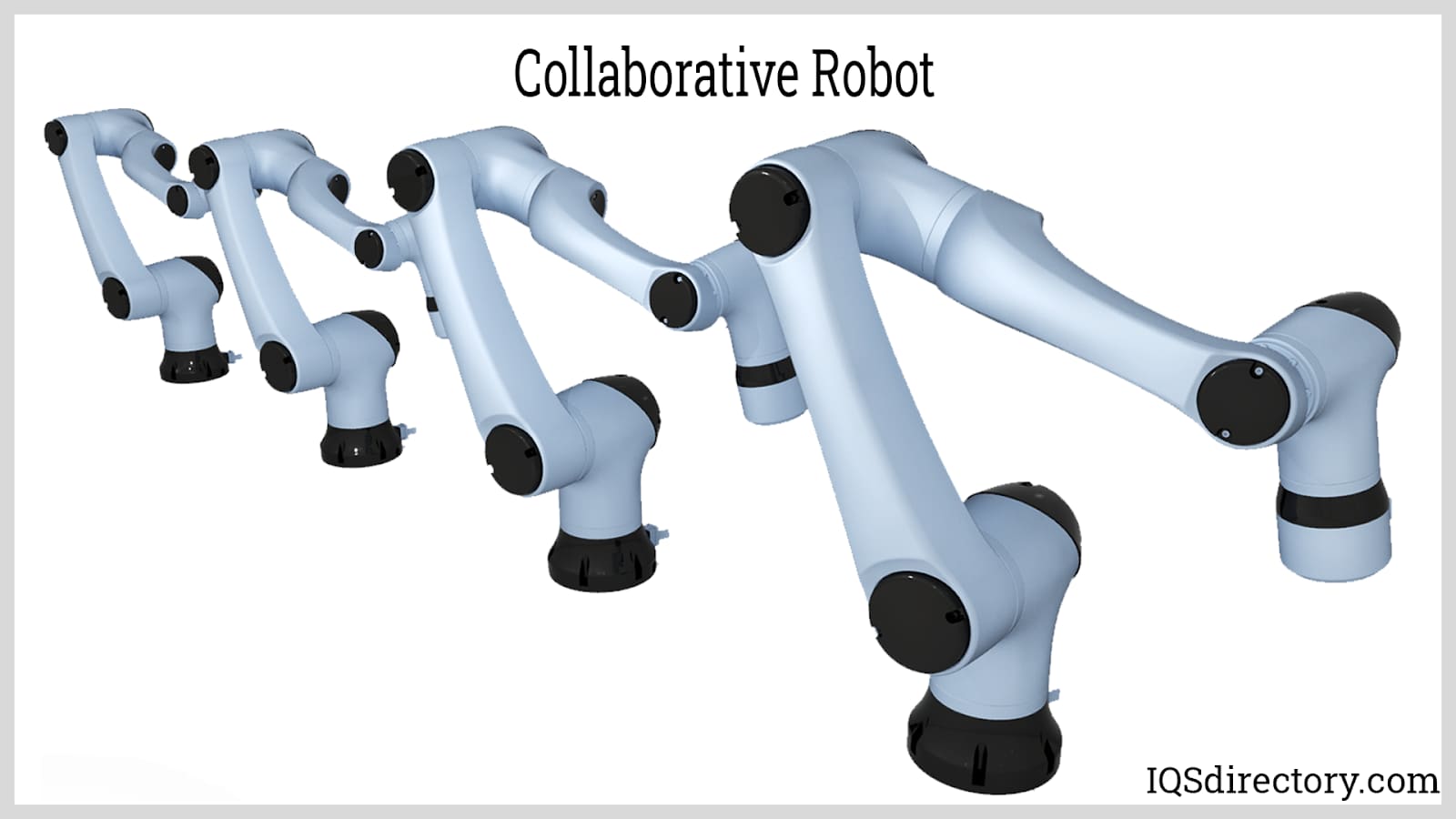

Robot Configurations

Robots fall into a wide variety, but they are mainly classified or grouped into six types when they are being discussed. These six types are namely selectively compliant arms for robotic assembly, polar, cylindrical, Cartesian, vertically articulated, and delta. These are just generalized categories; with today’s ever-changing technological advancements, many robots now fall outside such specific classifications.

Joints in robotic arms are known as axes. This is because arm movement can be in different planes concerning its design. A robot that has more axes has more freedom in its range of motion.

Classification of Robots

Robots are mainly classified based on their function by an international organization of standardization. The classifications are A, B, C, and D.

Class A and B – The A class of robots is usually for simple robots. These robots complete repetitive tasks. The B class of robots consists of those robots that can be programmed to perform jobs that need high accuracy and precision.

Class C and D – Class C robots are more advanced. They are programmable, have great strength, and can perform highly demanding tasks. Class D robots are the elite of robots. They include sensors that help them to read their surroundings and react accordingly to various stimuli. They can adapt their function according to the environmental conditions that surround them.

Types of Robots

The types of robots include:

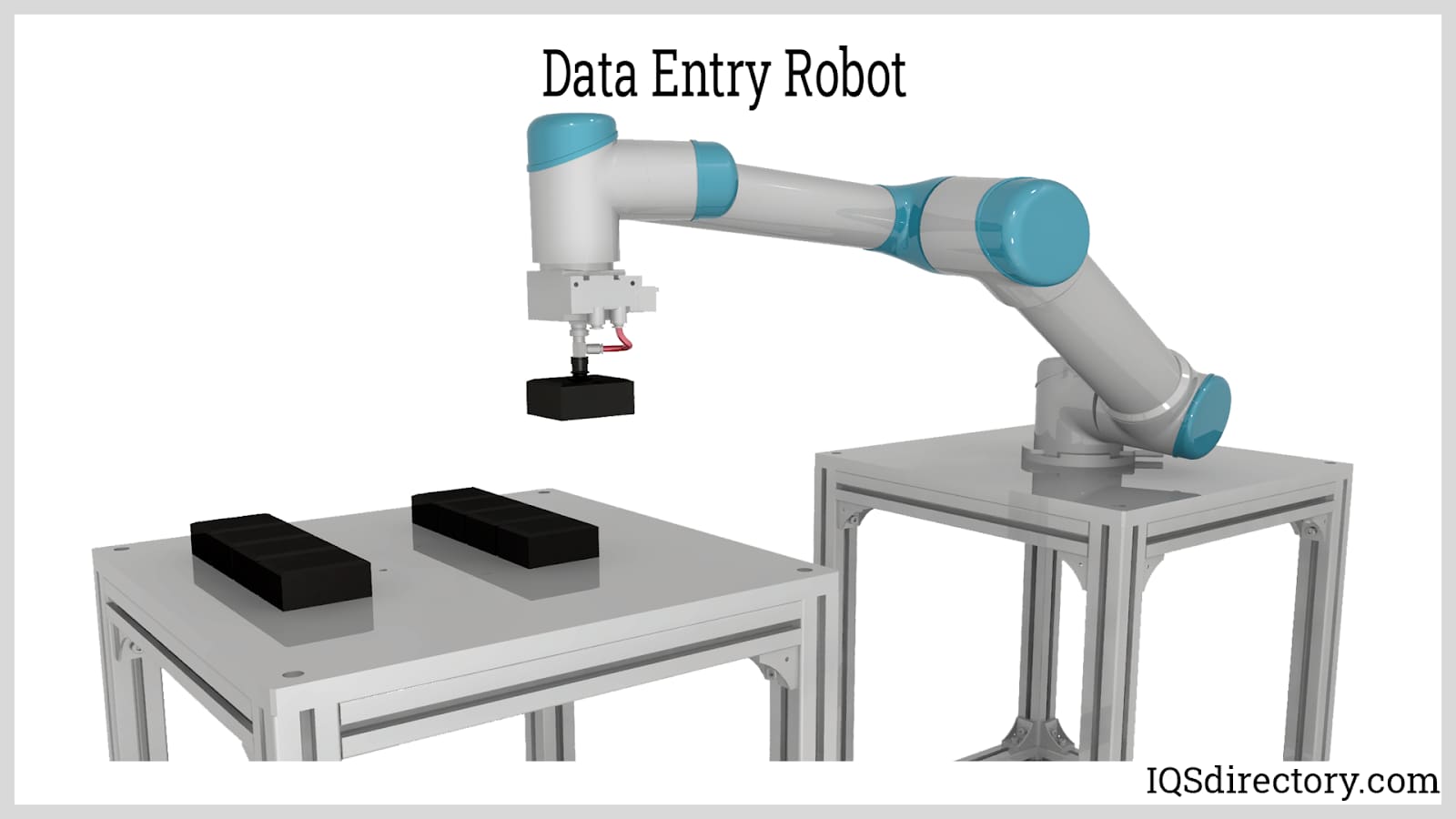

Data Entry Robots

Data entry is usually the final frontier of any automation process. Data entry involves swivel chair automation which is the “copying and pasting” of information. This step is usually performed between two application processes. Traditional data-entry methods are very slow. More importantly they are more error-prone and costly when performed by humans.

Data entry robots intervene by taking available electronic data and feeding it automatically to another system. Since the robots perform the tasks as a human being would, there are no complex or expensive integrations required to perform these tasks.

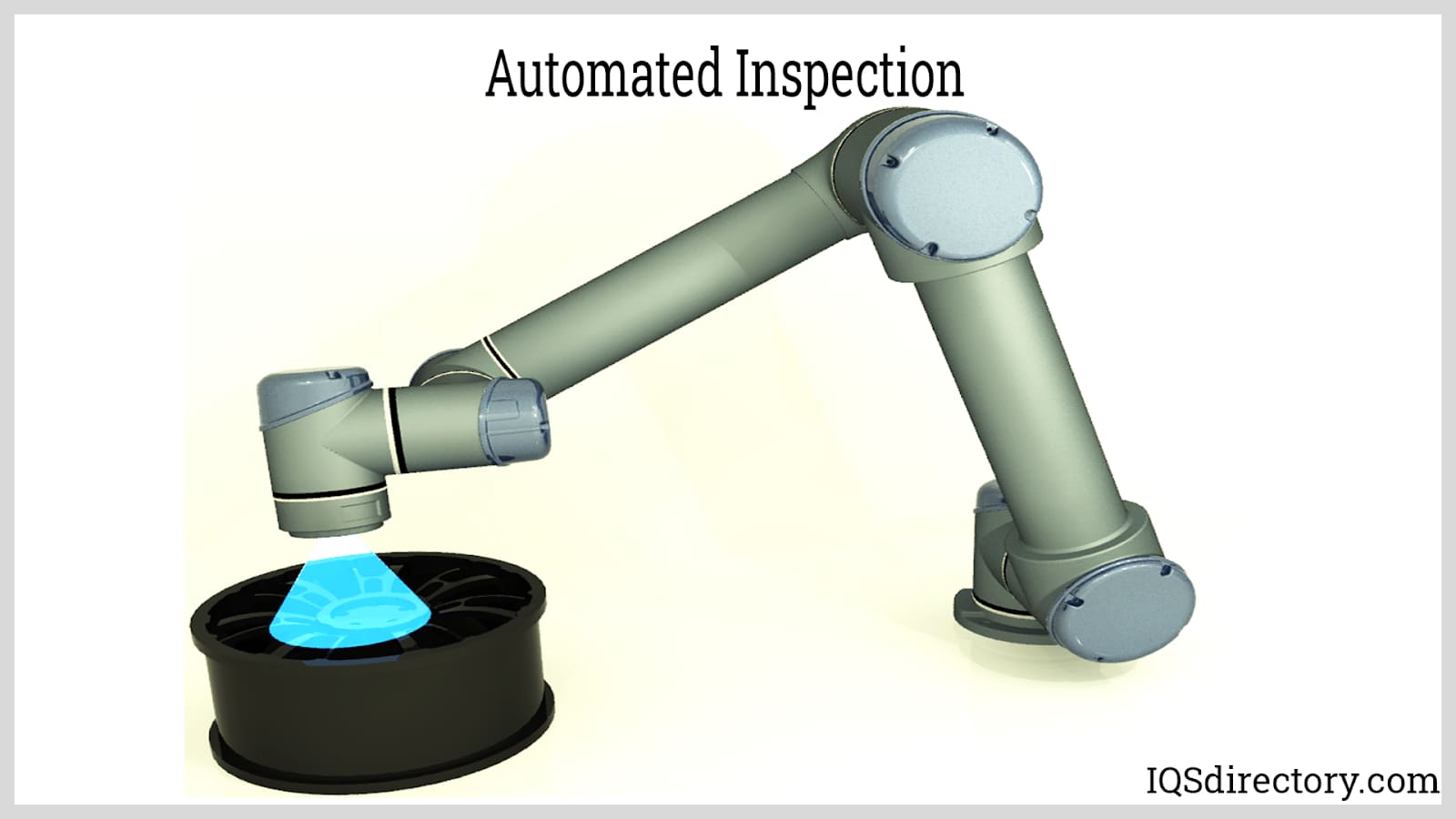

Validation and Verification Robots

Organizations may dedicate an enormous amount of time and effort on the validation and verification of the information they receive. Furthermore, there are also a lot of risks involved in doing these processes manually, making them unreliable and dangerous to corporations.

However, validation robots can perform real-time calls to a third party and internal system, allowing them to verify how authentic the information is. Validation and verification robots convert an unreliable and reactive process into a well-defined, proactive automation machine. Whenever a verification issue arises, the robot can bring the problem to the attention of its human co-worker who can handle it from there.

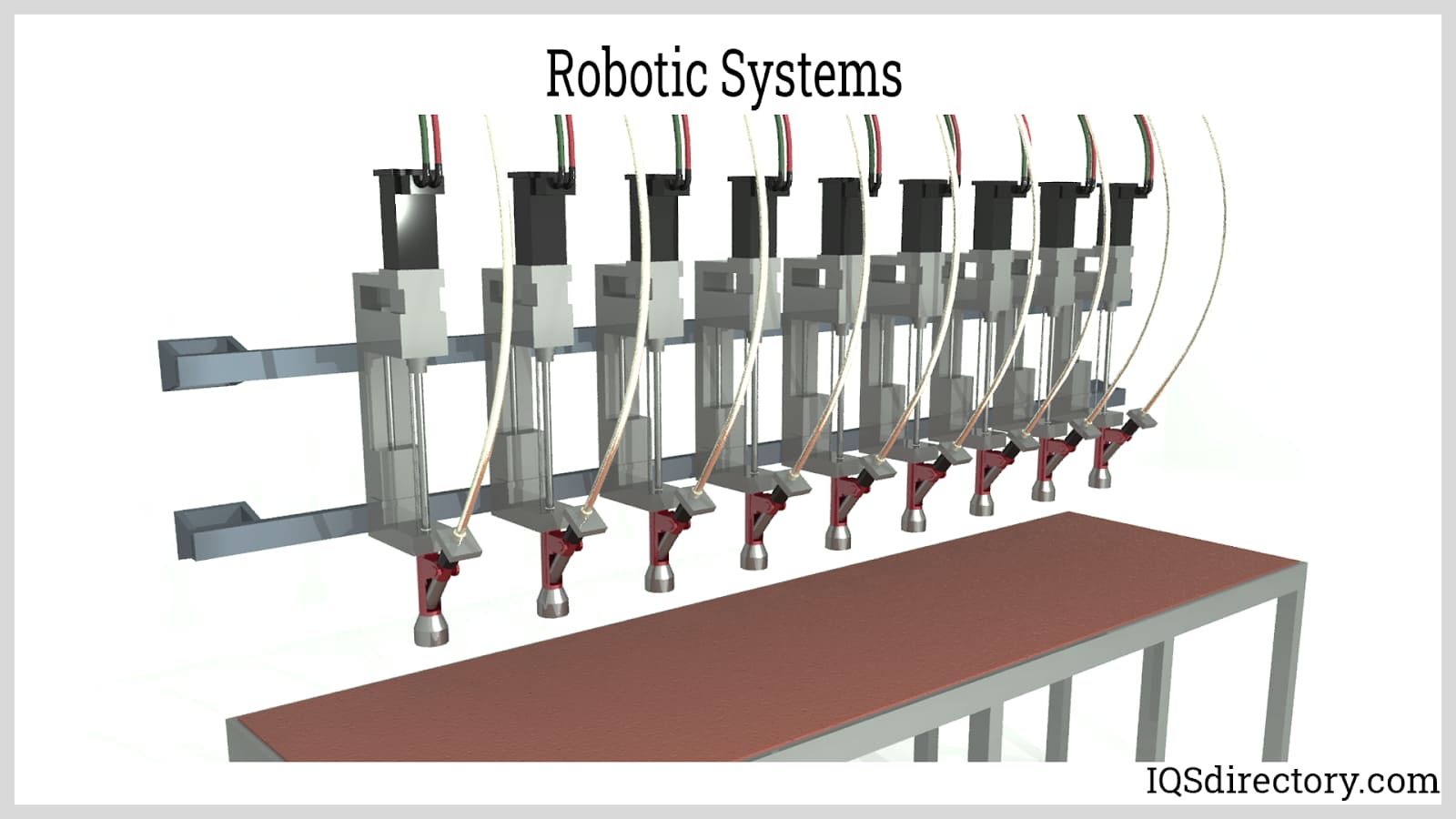

System Integration Robots

System integration robots are mainly employed to make traditional labor-intensive systems simpler and more efficient. Instead of employing a single type of robot to perform a specific task, these robots perform collaboratively with others to improve the efficiency of an entire production process.

Trigger / Scheduled Robots

These robots perform very simple tasks. These tasks, however, cannot be executed before a specific event is triggered. These robots work within regular intervals to execute their specific tasks in order not to miss any specified dates.

Applications of Robotic Automation

Robotic automation has been of great help in industrial areas for decades. Its use with emerging technologies and artificial intelligence has increased productivity and lower costs greatly.

Some of the industries and sectors where robotic automation systems are employed are provided below:

- Aerospace industry

- Pharmaceutical industry

- Medical facilities

- Automotive industry

- Agriculture

- Retail

- Manufacturing

- Mining industry

- Construction industry

Benefits of Robotic Automation

Manufacturing plants that require labor on a large scale for production of their different goods can increase and maximize their capabilities when they use automated robotic systems. A direct benefit is the money that is saved. There is room for greater productivity and accuracy when performing tasks that need repeated actions. The nature of work is elevated by the removal of repetitive, mundane tasks for employees. Robotic automation allows the use of robots to carry out tasks that are unsafe for humans thereby reducing the risk of injury and liability.

Robotic Automation Challenges

Some of the challenges to robotic automation implementation include:

Scalability

Although robotic automation software bots are generally simple to create, they may be challenging to regulate and manage, making it difficult for businesses to grow their RPA automation programs.

Specific Capabilities

Many critics have noted that many robotic process automation (RPA) software products automate only very specific tasks, even if their name contains the terms "process automation." Creating an entire workflow process frequently takes more effort coordinating several activities.

Choosing the Proper Robotic Automation Company

To make sure you have the most beneficial outcome when purchasing Robotic Automation from a Robotic Automation Supplier, it is important to compare at least 5 or 6 Companies using our Robotic Automation directory. Each Robotic Automation Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Robotic Automation company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Robotic Automation companies with the same message.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services