Applied Manufacturing Technologies

Applied Manufacturing TechnologiesRequest A Quote

Orion, MI | 248-409-2100https://appliedmfg.com/advanced-material-handling/robotic-machine-tending/

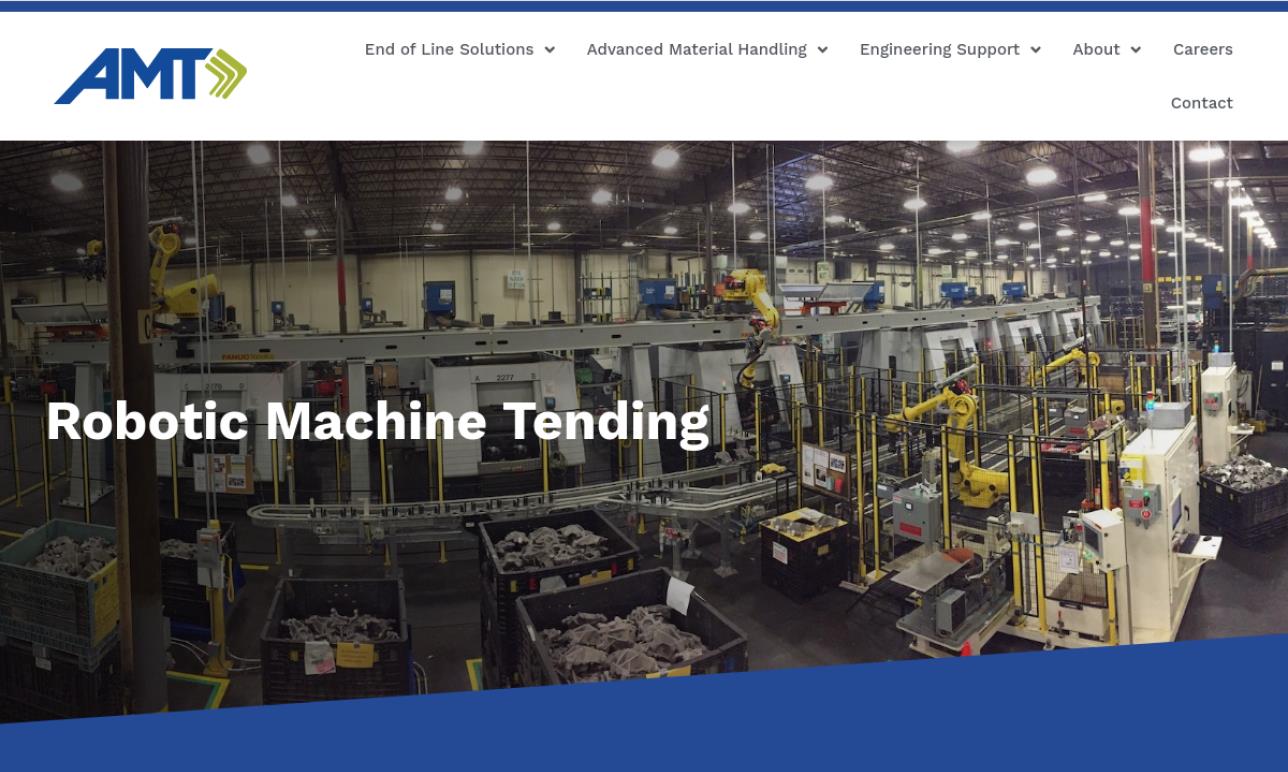

Applied Manufacturing Technologies (AMT) is a renowned company specializing in providing comprehensive Assembly Machinery solutions to industries worldwide. With a rich history of expertise and a strong commitment to customer success, AMT has established itself as a trusted partner in the field of manufacturing automation. AMT's core competency lies in the design, development, and integration of advanced Assembly Machinery tailored to the specific needs of their clients. Their extensive product portfolio includes a diverse range of automated assembly systems, robotic workcells, custom machinery, and turnkey production lines. These solutions cater to a wide array of industries, such as automotive, aerospace, electronics, medical devices, and consumer goods. AMT's team of experienced engineers collaborates closely with customers to understand their unique requirements and develop tailored solutions that optimize efficiency, flexibility, and productivity. AMT's Assembly Machinery products are characterized by their high quality, precision, and reliability. Leveraging their expertise in automation, robotics, and control systems, AMT delivers cutting-edge solutions that streamline assembly processes, increase throughput, and improve overall product quality. The company's machines incorporate state-of-the-art technologies, such as advanced robotics, machine vision, and intelligent software, enabling them to perform complex assembly tasks with speed, accuracy, and consistency. In addition to their innovative product offerings, AMT provides comprehensive services to support their customers throughout the entire lifecycle of their Assembly Machinery. Their services encompass system design, engineering, project management, installation, commissioning, and ongoing support. AMT's team of skilled technicians and engineers ensures seamless integration of their machinery into the client's production environment, maximizing efficiency and minimizing disruptions. They offer comprehensive training programs to empower operators and maintenance personnel with the necessary skills to operate and maintain the equipment effectively. AMT's commitment to customer satisfaction extends beyond installation and training. The company provides responsive support and maintenance services to ensure maximum uptime and productivity. Their dedicated service team is readily available to provide technical assistance, troubleshooting, and repairs, ensuring that any issues are promptly addressed. Additionally, AMT offers preventive maintenance programs and spare parts availability, helping customers optimize the performance and longevity of their Assembly Machinery. One of AMT's key strengths is their ability to provide turnkey solutions that integrate seamlessly into existing manufacturing processes. Their deep understanding of industry-specific requirements enables them to develop solutions that address unique challenges and drive tangible results. AMT's holistic approach combines the latest technologies, industry best practices, and a focus on lean manufacturing principles, resulting in optimized assembly lines that deliver superior quality products at a competitive cost. AMT maintains a culture of continuous improvement and innovation. The company invests in research and development to stay at the forefront of emerging technologies and industry trends. Through partnerships with leading technology providers and collaborations with academic institutions, AMT explores new frontiers in automation, robotics, and digitalization. This commitment to innovation enables them to offer cutting-edge solutions that help their customers achieve a competitive edge in their respective markets. In summary, Applied Manufacturing Technologies is a trusted provider of Assembly Machinery solutions, offering innovative products, comprehensive services, and a commitment to customer success. With their advanced technologies, industry expertise, and customer-centric approach, AMT is the ideal partner for businesses seeking to optimize their assembly processes, enhance productivity, and embrace the benefits of automation in manufacturing.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services